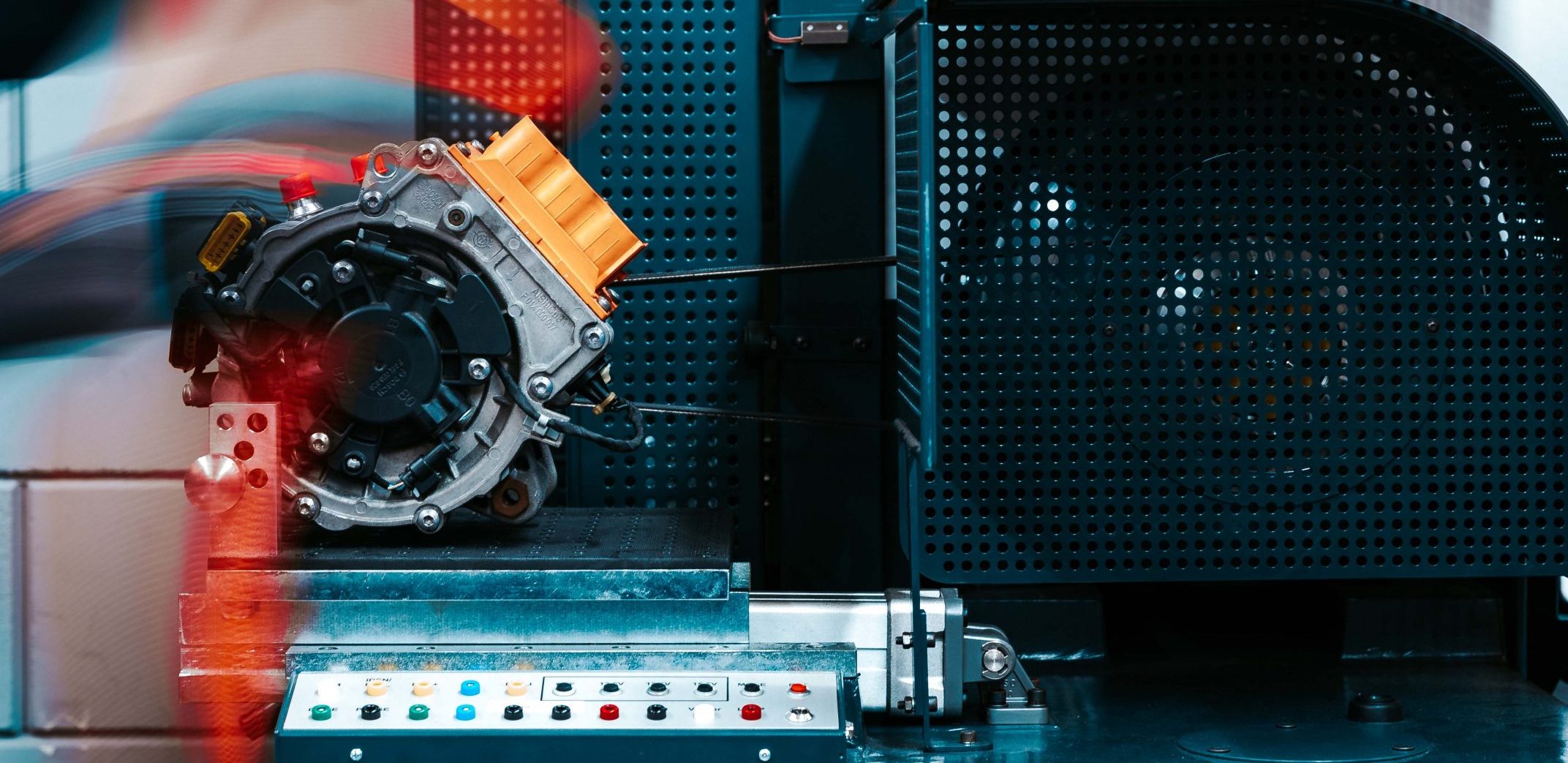

CV-307N

The CV-307N. This is a small and easy to use test bench, which has all the modern functionalities like the CV-615A. It is equipped with a 7,5KW 380V 3 phase motor and its maximum load is 300amps.

The CV-307N is equipped with the latest testing technology for the modern workshop or production facility, such as API+ technology which automatically identifies COM protocols within 2 seconds. These protocols are displayed together with their ID codes, which makes development in remanufacturing easier, cheaper and more clear.

Features

- Sturdy frame designed to last

- For workshops and warranty departments

- 380V 3 Phase

- 12/24volt testing

- 300A (12Volt)/150A (24Volt)

- 7,5KW motor (10HP)

- @12V 4x32A/3x45A/45x1Amp resistors

- Leakage test up to 250mA

- Ripple measurement in Amps and %

- Alternator Efficiency in %

- Motor torque test in NM

- Motor power in KW

- Voltmeter accuracy 0,1 volt accuracy

- Amp meter 0,25% accuracy

- 2-way pneumatic tensioning

- (V) belt drive

- Extensive manual testing features

- Bright colored displays

- Step less rpm control

- Step by step load control up to 300amps

- API+ high speed automatic protocol identification

- Tests 24V LIN

- Extensive regulator control

- Displays regulator errors

- Shows unique regulator ID codes

- Shows communication speed in Baud rate

- Tests all PWM controlled alternators even 24 Volt

- In depth DFM testing

- Auto testing capabilities + wizard learning mode

- Preset Database (can be adapted by customer)

- Auto test plug harnesses

- Manual select knob for auto/manual testing modes

- PC included

- Small high-end computer (windows 10) and wide screen monitor included.

- New developed software layout (can be adapted in any way)

- Auto test function even without computer

- Software is Windows compatible

- LaserJet printer

- Extensive report printing with performance curve

- Sturdy mounting accessories and plugs included

- Reliable tester and ready for the future and can be updated easily

- Fast service and support

- CE certified

RELIABLE & PROFESSIONAL EQUIPMENT

Features

- Sturdy frame designed to last

- Production/end-of-line tester (Optional)

- Standard alternator, starter and regulator tester in 1

- 380V 3 Phase

- Motor: 22kW

- Resistors: 600A @ 12V, 400A @ 24V (linear with 0-50A PWM)

- Future options can easily be upgraded for 48V (unique resistor box design)

- Test-bench controlled by Siemens PLC Siematic S7

- High-end custom-made alternator control unit

- Manual select knob for auto/manual testing modes

- Belt drive

- High-end Safety cover with pneumatic fastening (Option)

- Filtration in bottom part against dust (Option)

- Extensive manual and automatic testing features

- Dual pneumatic tensioning system

Computer

- PC built-in Intel NUC

- Professional PC software in any language

- New 2019 developed software layout

- Heavy duty membrane keyboard

- Heavy duty touchscreen dedicated for Siemens PLC

- SCADA language

- SQL database

- Motoplat software is Windows compatible

- APC battery built-in for computer stability and reliability

- Full customizable test procedure

- LaserJet printer or label printer(option)

- Extensive report printing with performance curve in any language

- Internal router for updating, service, maintenance

- Calibration through internet

Testing Capabilities

- API+ high speed automatic protocol identification (30 protocols with over 200 regulator ID’s)

- Tests 24V LIN and DFM

- Displays all regulator errors

- Shows unique regulator ID codes over 200codes

- Tests starting mode BSG’s

- Ready for 48V BSG units

- Ford RVC testing

- Shows communication speed in Baud rate

- 3 VSP/RPM measurements for regulator reliability

- W terminal testing Hz@RPM

- Tests all PWM controlled alternators even 24 Volt

- In depth DFM testing V/Hz/PWM % @ high and low load

- Leakage test up to 250mA

- Ripple measurement in Amps and %

- Alternator Efficiency in %

- Alternator torque check in NM

- Checks alternator power in KW

- Voltmeter accuracy 0,1-volt accuracy

- Amp meter 0,25% accuracy

- External regulators for 12v and 24v built-in

- Regulator tester built-in

- Starter testing IST type units testing as „starter”

- Advanced auto testing capabilities

- Wizard learning mode for database building -> comparison testing

- Step less or computer-controlled rpm adjusting

- Step by step load control up to 600Amps

- Oscilloscope built-in software

- Preset Database (can be adapted by customer)

- Endurance Test(option)

Accessories and other features

- Sturdy mounting accessories for normal and pad mount

- Pre-connected harnesses and plugssets included

- Belts included

- Reliable tester and ready for the future and can be updated easily by internet

- Easy servicing because of interchangeability of PCB’s

- Connectivity between tester and internet for fast support -> quick problem solving

- Fast service and (online)support

- Battery chargers built-in

CV-623A

Motoplat has developed a brand new test bench other than anything out there today. The new CV-623A brings all testing aspects into one test bench: advanced alternator testing, starter testing and regulator testing.

New PLC controlled tester in combination with C++, Scada and SQL software platforms will ensure reliable testing and easy servicing capabilities all over the world. This is the most competitive alternative for any other test bench brand out there on the market today. It easily identifies over 30 LIN and 3 BSS protocols together with over 200 ID codes and in-depth transmission data.

APPLICABLE FOR EVERY ALTERNATOR

CV-623P

By shifting the standard CV-623A 90 degrees we have created a user-friendly side mounting tester. Still keeping the main components of the tester the same but smaller to fit more efficiently in a production line. The CV-623P is capable of achieving a 22second cycle time in a production environments.

Motoplat has developed a brand new test bench for 2019 other than anything out there today. The new CV-623 brings all testing aspects into one test bench: advanced alternator testing, starter testing and regulator testing. New PLC controlled tester in combination with C++, Scada and SQL software platforms will ensure reliable testing and easy servicing capabilities all over the world. This is the most competitive alternative for any other test bench brand out there on the market today. It easily identifies over 30 LIN and 3 BSS protocols together with over 200 ID codes and in-depth transmission data.

Main Features

- Sturdy frame designed to last

- Production/end-of-line tester (Optional)

- Standard alternator, starter and regulator tester in 1

- 380V 3 Phase

- Motor: 22kW

- Resistors: 600A @ 12V, 400A @ 24V (linear with 0-50A PWM)

- Future options can easily be upgraded for 48V (unique resistor box design)

- Test-bench controlled by Siemens PLC Siematic S7

- High-end custom-made alternator control unit

- Manual select knob for auto/manual testing modes

- Belt drive

- High-end Safety cover with pneumatic fastening (Option)

- Filtration in bottom part against dust (Option)

- Extensive manual and automatic testing features

- Dual pneumatic tensioning system

Computer

- PC built-in Intel NUC

- Professional PC software in any language

- New 2019 developed software layout

- Heavy duty PC touch screen

- Heavy duty membrane keyboard

- Heavy duty touchscreen dedicated for Siemens PLC

- SCADA language

- SQL database

- Motoplat software is Windows 7, 8, 8.1 and 10 compatible

- APC battery built-in for computer stability and reliability

- Full customizable test procedure

- LaserJet printer or label printer(option)

- Extensive report printing with performance curve in any language

- Internal router for updating, service, maintenance

- Calibration through internet

Testing Capabilities

- API+ high speed automatic protocol identification (30 protocols with over 200 regulator ID’s)

- Tests 24V LIN and DFM

- Displays all regulator errors

- Shows unique regulator ID codes over 200codes

- Tests starting mode BSG’s

- Ready for 48V BSG units

- Ford RVC testing

- Shows communication speed in Baud rate

- 3 VSP/RPM measurements for regulator reliability

- W terminal testing Hz@RPM

- Tests all PWM controlled alternators even 24 Volt

- In depth DFM testing V/Hz/PWM % @ high and low load

- Leakage test up to 250mA

- Ripple measurement in Amps and %

- Alternator Efficiency in %

- Alternator torque check in NM

- Checks alternator power in KW

- Voltmeter accuracy 0,1volt

- Amp meter 0.25% accuracy

- External regulators for 12v and 24v built-in

- Regulator tester built-in

- Starter testing IST type units testing as „starter”

- Advanced auto testing capabilities

- Wizard learning mode for database building -> comparison testing

- Step less or computer-controlled rpm adjusting

- Step by step load control up to 600Amps

- Oscilloscope built-in software

- Preset Database (can be adapted by customer)

- Endurance Test(option)

Accessories and other features

- Sturdy mounting accessories for normal and pad mount

- Pre-connected harnesses and plugssets included

- Belts included

- Reliable tester and ready for the future and can be updated easily by internet

- Easy servicing because of interchangeability of PCB’s

- Connectivity between tester and internet for fast support -> quick problem solving

- Fast service and (online)support

- Battery chargers built-in